Are you searching a suitable and reliable pattern making software for your production house or garment industry? Do you need a user friendly, modern, responsive pattern making software for your pattern section? Pattern making process is necessary to run an apparel business smoothly. Before it accomplished manually, but now it’s quite impossible to run it perfectly considering time, situation and business volume. Usually, pattern making software abbreviated as CAD which elaborated as computer aided design. In fact, it has known as design making software which can assist you to optimize your sketches. Once pattern making task was tough and clumsy because all tasks handled by a skilled technician. But now it becomes very easy due to the advancement of computer technology.

CAD is an integrated system which is used for pattern making, pattern grading, measuring as well as marker making. Some company also delivers automatic fabric spreader, automatic fabric cutter, end cutter, CAM cutter, plotter, and pattern cutter devices to smooth your operations. It is an essential element in garment export house, fashion school or medium and large size garment business. CAD system is not only useful for clothing business but also helpful to other professionals to create a dynamic design. CAD system is a unique process where a pattern maker can transform a sketch into a digital image and then can be printed out through a plotter. Moreover, by this practice pattern maker can justify image efficiency before print out through 2D / 3D special visual effects.

AIMS 360 is the #1 apparel software in the industry! Currently powering over 600+ manufacturers, wholesalers and importers of apparel, footwear, accessories and other fashion-related goods. This affordable business software gives you total control! The main advantage of is that the software is instant allowing faster customization thus reducing manual efforts. This software generated pattern can be used on any fabric. Tailoring software allows quick turnarounds and customization at larger scales. Customers do not face fitting problems. Repeated process of reusing the pattern is possible.

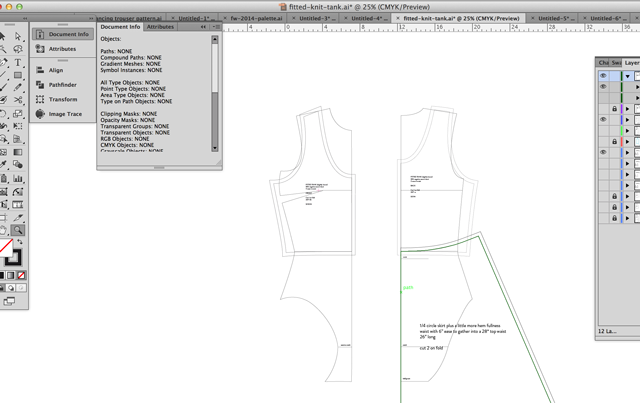

Garment plotter machine

It’s obviously a great solution that can improve sample room productivity, accuracy and help you to easier cutting room tasks. Thus, garment owners always emphasize to procure a best pattern and marker making i.e. CAD software for their respected organizations to get optimum result. CAD software is specially designated to accomplish computer aided design correctly. This software’s are capable of bringing a good shape of any curve line. Usually, a bunch of computer engineers, skilled technicians, and professional designers have to engage to build any particular CAD software. Nowadays most of the CAD software’s support 2D / 3D special visual effects. Wherever you factory are situated, CAD service providers can serve you easily because they have a global presence through the internet or local agents.

Today, I will try to share some renowned pattern making software’s name in this post. Beside this, you can get more information regarding these software’s by reading the product features or visiting their websites. I think this post just gives you an idea to choose a suitable CAD solution for your garment industry.

1. Crea: It is worldwide recognized as the most intuitive and easy to use CAD for pattern making, size grading and made to measure. Developed on the windows interface for the pattern makers that are totally autonomous after only 3 days of training. Headquartered in Italy, and grown up working with the most popular fashion brands of the world, Crea Solution has developed the complete CAD CAM for fashion & apparel suite equipped with all direct importers of other CAD formats. Crea is having a huge success even in industries like aerospace, furniture, automotive, bespoke and made to measure, technical textiles and composite garment industry.

2. Lectra: It is one of the worldwide renowned CAD software for garment entrepreneurs. They have developed a high-end CAD solution for the fashion industry. Pattern makers love to use Lectra for its simplicity and powerful features. It also admired in fashion and apparel, furniture, automotive as well as other industries like composites, textiles, and leather. Their cutting solutions are perfect for smooth operations. Their headquarters situated in Paris in French.

3. Gerber Accumark: It is one of the popular CAD software for garment manufacturers. This software is user-friendly along with advanced features. It’s a comprehensive and full-featured CAD pattern making software for the apparel industry. Their software and hardware solutions are perfect for fashion & apparel, aerospace, construction, packaging, furniture, automotive industry, technical textiles, digital printing, graphics industries. Their headquarters situated at West Tolland in the USA.

4. GT CAD Software: You will be glad to know that it’s a Bangladesh-based company. They can deliver quick service regarding pattern design and marker making software. It is an integrated and accurate pattern making software for perfect fitting garments. Their interface has designated very simply so that everyone can handle it quickly.

5. Optitex: It exists 2D and 3D pattern making option with a lot of advanced features. You can use their package by paying low subscription to get lifetime customer support. It was a startup venture of Silicon Valley. Their CAD, pattern, cutting solutions are easy to use for all apparel industries.

6. Etelestia: Telestia formed by the Fashion School SITAM-AB in Greece on 2004. It is a comprehensive and full-featured CAD pattern making software for the apparel industry. Their 2D & 3D CAD/CAM solutions are perfect for Pattern-Designing, Grading, detailing, marker layout and CAD drafting in Garment industry.

7.Tuka Cad: It’s appropriate for Pattern-Designing, Grading, and Marker-Making in Garment industry. You can use their service by paying low monthly subscription to get their premium service. They also provide free online unlimited training for their subscribers. Their software’s are perfect for accurate measuring. Their headquarters situated in Los Angeles in the USA.

8. Fashion CAD: They have an integrated pattern making software for high-end customers. Their CAD solutions are user-friendly for pattern drafting, modification, grading, pattern cloning, detailing, and marker making. It is an Australia-based company.

9. Richpeace: They have a complete CAD solution for pattern making, pattern treatment, grading, detailing, editing, pattern cutting. It can be downloaded from their official websites by paying low yearly subscription. Their headquarters situated at tianjinshi in China. They also provide different types of cutting & sewing machine, embroidery, quilting machine.

10. Gemini CAD Systems: They provide integrated software and hardware solutions for pattern creation, modification, measuring, grading, pattern cutting including 2D and 3D pattern making option. It is a Romania-based company.

11. PAD Systems: It’s powerful but easy software for pattern designing, grading, pattern alteration, cloning. It has some user-friendly Interface for making innovation. Thus, you can choose it for your production unit. It invented by iWork Ltd, a Hong-Kong based company.

12. Romans CAD: It is innovative and dynamic software for manufacturers and designers to accomplish Pattern Making, Pattern Treatment, Grading, and Marker Making Solution. Their sophisticated solutions are especially admired in footwear and leather goods industries to accomplish the critical task. Their headquarters situated at rungis in French.

13. Dimension CAD: It is an advanced pattern making, grading, editing, eliminating, and marker making solution that will make more efficient your production process and reduce operating cost. It is also an idle and affordable pattern making software for home based or commercial businesses. It situated in San Diego in the USA.

14. Wild Ginger: Do you need custom-sized sewing patterns or professional pattern making software? Wild Ginger publish the most comprehensive and cost-effective range of pattern making software on the market. It exist many custom features for pattern creation, grading, pattern tampering, marker-making, mass customization and custom mode of tailoring. You can use their education version without free of charge.

Companies overall profit and loss mostly depend on pattern and marker making section efficiency. Thus, an owner should select a premium CAD solution to chase the goal. You are requested to click my google drive link to get a fantastic guideline regarding pattern making process. Please hit the link to download your desired file.

Here I have tried to compile all user friendly pattern making software for your reference. I think you will get a clear instruction that may assist you to learn pattern making task quickly. There are a lot of resources on this topic in the online world. If you wish to learn pattern making job properly through the internet, at first I am humbly requesting you to download individual software trial or education version without free of charge. Once you become expert then you may purchase full license software from above mentioned individual software link.

You may like: Procedure of Pattern Making

Pattern making refers to modifying a flat piece of fabric to create a garment that suits the proportions of a human body. It is the building block of fashion design. For a career in Fashion designing, Pattern Drafting is a necessary skill to know. Pattern makers, costume designers, Ready to Wear fashion designers, sewing business owners, home sewists – they all need this knowledge, in varying degrees of expertise.

There are many methods of pattern making.

The most sophisticated and easy way is to let a computer make all the patterns. Garment manufacturers depend on these computer software programs for creating patterns with the help of talented fashion design professionals. It is super fast and without too many errors. But it is costly, so the next best recourse is manual pattern drafting.

Manual pattern making is done by following 2 primary methods.

Flat pattern drafting Method (with block patterns) & the Draping method.

Flat pattern drafting

This is a method of making a drawing of the garment on a pattern paper, based on body measurements, following the design on a fashion sketch. It is supposed to be the most accurate manual pattern drafting method.

The basic, foundation patterns are called slopers. The sloper has the bare minimum ease. It basically fits the figure to a T.

The basic slopers are then modified to make different types of other complicated, feature rich flat patterns. The slopers are modified and manipulated by adding ease, and other design elements like fullness, tucks, change in design lines etc.

Fashion sketches are flat, Patterns are flat. Clothes are definitely not. It is the design elements like darts that give depth and dimension to flat patterns. Slashing and spreading of the sloper pattern adds more fullness to the pattern, Darts are added to give a 3D effect, fabric manipulations are done to add texture to the fabric.

Draping Method

This is a method of draping the fabric on a dress form and then make the pattern from there. The fabric for the garment (or a muslin fabric) is pinned directly on to the mannequin and adjustments are made, tucks, darts and curves are pinned and the markings made with chalk.

This method enables the designer to clearly see how a particular fabric drapes and how it will look as a final garment. If you want to visualize your design in a 3 dimensional way and then make the pattern, this is the method for you.

The draping is almost always converted to a flat pattern, before making into the final garment.

It involves a lot of steps and can lead to error if you are not experienced. Some fabric looks way better on a dress form than on a human body, with all the movement involved and other details. Draping is not a good choice for sewing with close fitting styles or when designing with stretchy fabrics.

But for a creative person, this can involve a great deal of innovation and satisfaction.

19th century French fashion designer, Madeleine Vionnet, was a pioneer in creating garments by draping.

After the Pattern is made, the finished pattern and the toile made out of it will have to be tested on the dress form with the exact measurements for fit.

You have to analyse if the bodice length on the back and front are adequate, the shoulder slope is accurate, the armscye is perfect, there is balance on both sides of the pattern, whether the ease is adequate for comfort as well as movement, whether the pattern instructions are enough for even novices to sew it etc. Only then will your garment turn out to be the best.

Pattern making Vocabulary

Sloper : Master pattern made based on the correct measurement of the body. This is the basis on which other patterns are developed (foundation pattern/master pattern). Once you have made this you will be able to design garments in any style to fit the person. Slopers can be made of Bodice, skirt, sleeves, pant and collar.

Fitting Shell : Another name for sloper; a Closely fitting pattern without any design features and bare minimum ease.

Block : Basic starting pattern for a particular garment. This pattern will have design elements.

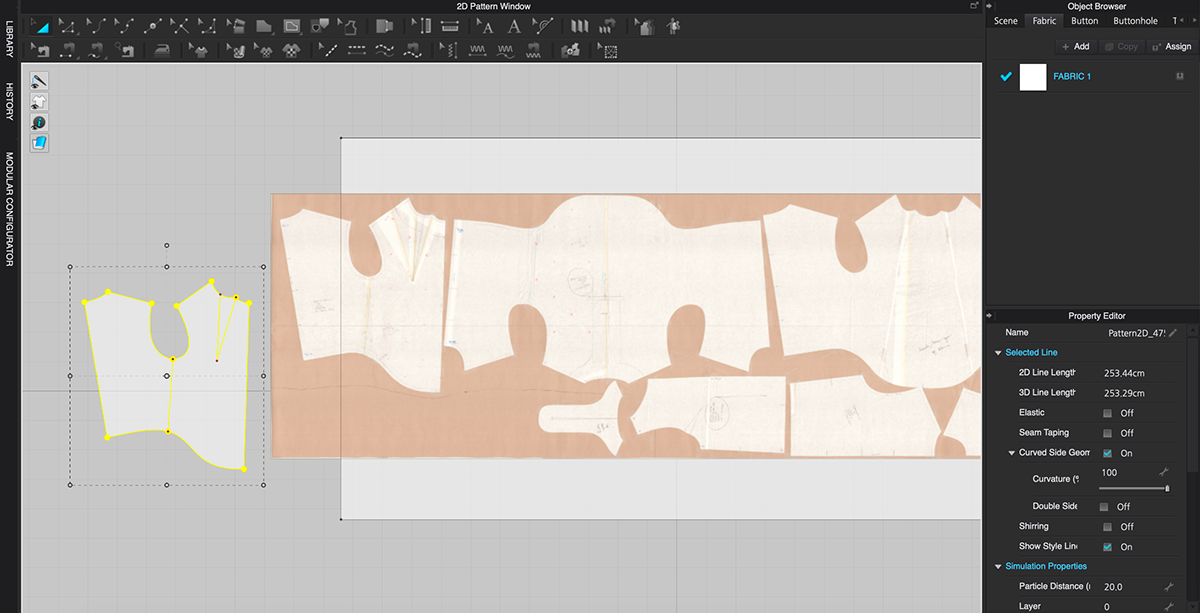

Free Fashion Pattern Making Software

Production Pattern : The final error free pattern developed after all corrections are done. It is ready for production.

Bodice : Part of the garment from shoulder till the waist.

Bust line : Line around the fullest part of the bust.

Waistline : Line connecting bodice to the skirt on a dress; Line around the narrowest part of the torso.

Hip line : Line around the fullest part under the waistline.

Toiles/Mock ups : The sample garment made from the pattern. Pattern created using the methods described above are then tested using toiles and mockups.

Dress form/Body form : Body shaped forms in fixed proportions.

Ease : Extra measurement added to the garment for ease of movement and comfort.

Trueing : Adding seam lines after the sloper is fitted on the dress form.

Pattern Drafting software : Computer programs for pattern making in garment manufacturing. These allow you to simply input your measurements and the drafting of the pattern is done by the software. You can even convert the pattern into a 3 D model with the help of these software. CAD programs like Inkscape are widely used.

Pattern drafting tools : Large Pattern making paper, a narrow one meter long measuring tape, pencils, Erasers, Large clear grid scale, dress form, Curved scales (Leg curve, hip curve), scissors for paper.

Standard Measurements : These refers to body measurements that are used in commercial patterns. These are not individualized and cannot be for commercial patterns. So garments made with these patterns can fit less optimally than ones made with personalized body measurements. Standard pattern figure types like Misses, Miss Petite, Junior, Women’s Women’s petite Men’s and kids are used by commercial pattern companies who sell patterns for home use.

Muslin Rub : Term that refers to rubbing tailor’s chalk on the muslin fabric used in draping, to indicate seam lines and darts.

Marks on a Pattern.

Seam line : A sewing machine foot is the symbol for sewing line on patterns.

Seam Allowance : The extra fabric further from the seam lines.

Seam Numbers : Numbers on patterns showing which seams are to be sewn to one another.

Cross marks : The marks along seams etc used to indicate where sections meet.

Free Clothing Pattern Making Software

Grain line : This is direction of the grain of the fabric. It should be marked along the length of the pattern pieces as a line.More on grainline here

Patterns Fashion Design

Pattern details : The pattern will be accompanied by a pattern guide sheet with all the details needed for interpreting the patterns and result in the final garment. Pattern Parts and sizes and number of pieces are always marked on the pattern.

Notches : Pattern indicators on patterns for matching seams. There can be single notches and double notches. They can be added to denote seam allowance, dart legs. Double notches are given on back pattern to distinguish it from the front pattern.

Circles : Pattern indicators for dart points, tucks, buttonholes.

Fitting symbols : These marks are placed on long seams so that accuracy is maintained when sewing the seam.

Cutting lines: Symbol of scissors to show where fabric should be cut.

Pleat symbols: Arrows showing pleat positions.

Fold line : Broken lines showing where fabric should be kept on fold.

Pattern Marking short forms

Fashion Patterns Free

CF – Center Front

CB -Center Back

BP – Bust Point

SS– Side seam

SW – Side Waist

SH– Shoulder

HBL – Horizontal Balance Line

SH- Tip – Shoulder tip

Reference : Reader’s Digest Complete Guide to Sewing.

Related posts : Best sewing pattern sites ; Free sewing patterns.